Choosing the most suitable fridge or freezer for your lab’s requirements can be tricky, particularly if you want to purchase more sustainably, but without impacting your workflows or the security of your samples and reagents. Unfortunately, it’s not as simple as selecting the most energy efficient unit on the market.

Recent studies conducted by independent laboratory sustainability specialist, Green Light Laboratories highlighted several factors that could be considered when purchasing your lab fridge or freezer (in addition to energy efficiency data). These studies looked at:

- Door opening recovery

- Temperature setpoint

- Temperature performance

- Door type—glass or solid

- Freezer furniture—impact of solid drawers

In this article, we’re going to look at temperature setpoint and performance, and freezer furniture. Read on to find out more about how these factors can influence appliance suitability and energy conservation in your lab.

Temperature set point and performance

If you’re storing high value and/or temperature sensitive samples in your lab fridge or freezer, then choosing a model that delivers reliable temperature performance is important. Fridges with fan circulation will reach setpoint temperature faster than those without, and recover their temperature more rapidly after a door opening (view part 1 for more information).

For -20 °C laboratory freezers, the ability to adjust and accurately set the temperature can be useful for energy conservation. During testing, reducing the setpoint temperature of a small under bench freezer from -23 °C to -25 °C increased its energy consumption by 7%.[1] Whilst changing the setpoint temperature from -20 °C to -30 °C in the freezer compartment of laboratory-grade fridge freezer more than doubled the energy usage of that compartment.[2] Therefore choosing a model that enables you to precisely set the temperature to the warmest suitable for your requirements could provide useful energy savings.

One energy saving tip for ULT freezers is to increase the temperature from -80 °C to -70 °C. In a recent study, featuring the Stirling Ultracold SU780XLE freezer, energy consumption dropped from 8.864 kWh/day to 6.710 kWh/day when the setpoint was raised to -70 °C.[3] However, this guidance is contingent on the temperature performance of your freezer. You’d want to be confident that, like the SU780XLE, when your ULT freezer is set to a warmer -70 °C it delivers good temperature stability throughout the interior and that it recovers effectively after any door openings.

Laboratory freezer furniture and door opening recovery

What have drawers got to do with it?

More than you might think… In fact, the energy cost of opening your freezer door could be up to 5x as much if your freezer does not have drawers. Drawers have a positive effect on temperature stability when the door is opened and result in quicker temperature recovery times. The examples below demonstrate the benefit of having drawers (all data provided by Green Light Laboratories; full case studies available on request).

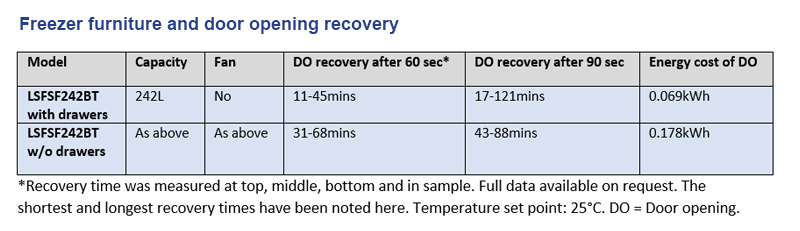

Example 1:

The Lec Medical LSFSF242BT 242 L laboratory freezer is supplied with 6 drawers as standard.

With these drawers in place, the temperature rose between 0.4 °C and 2.5 °C when the door was opened for 60 seconds; and between 0.9 °C and 3.8 °C with a 90 second door opening.

However, when the drawers were removed: The temperature rose between 8.4 °C and 15.9 °C when the door was opened for 60 seconds; and between 14.0 °C and 22.8 °C with a 90 second door opening.

The temperature increases were between 8x and 17x higher without drawers in place. Furthermore, the energy required (i.e. the cost) to recover from door opening without drawers in place was over 2.5x higher (158%). The average recovery time for each part of the freezer (top, middle and bottom) was quicker with drawers in place (full data available on request).

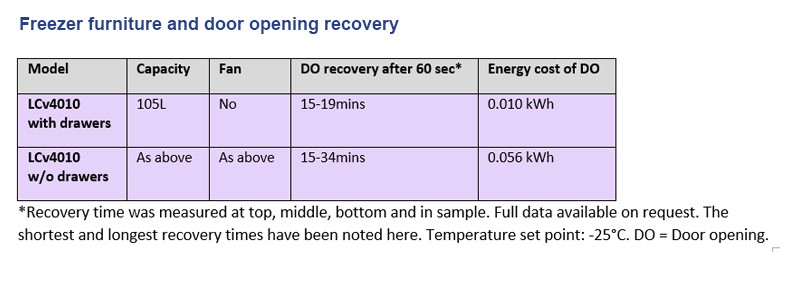

Example 2:

The freezer compartment of fridge freezer LCv4010 is supplied with 3 solid drawers as standard.

With these drawers in place, the temperature rose between 0.8 °C and 1.8 °C when the door was opened for 60 seconds.

When the drawers were removed: The temperature rose between 3.7 °C and 11.6 °C with a 60 second door opening.

In fact, the middle section of the freezer showed a rise in temperature over 10x higher when drawers were removed: 0.8 °C compared with 11.6 °C. What’s more, the energy required to recover from door opening without drawers was over 5.5x higher than with drawers in place. Full data available on request.

Fridge and freezer organisation

Why is it important to keep your fridges and freezers organised?

Put simply: Opening your fridge or freezer door uses additional energy.

How long the door is open affects how much the temperature will rise within the compartment (although this does vary between different areas of the chamber) and how long the unit will take to recover to its setpoint. In turn, this affects the amount of energy required to bring the unit back to its setpoint. Exactly how much additional energy depends on how long the door is open and whether the unit has a fan (fridges) or drawers (freezers), amongst other things.

In addition, frequent and prolonged door openings of freezers will lead to ice-build up and reduced running efficiency. For this reason, good energy conservation practices include:

- Using an inventory management system that allows you to quickly locate what you need and minimise the amount of time that the door is open

- Storing regularly required items nearer the front of the fridge or freezer

- Keeping the contents tidy and throwing out unwanted reagents and samples

- Opting for freezers with drawers rather than shelves

The example below demonstrates why it can be helpful to keep door openings (number and duration) to a minimum (all data provided by Green Light Laboratories).

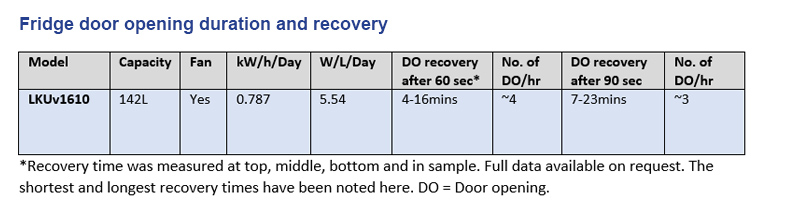

During testing, the LKUv1610 (142 L) underbench fridge showed a temperature increase of between 1.1 °C and 3.7 °C (depending on the compartment) when the door was opened for 60 seconds.* This rose to between 1.5 °C and 5.4 °C with a 90 second door opening. The duration of the door opening also impacted the number of door openings per hour that the unit could manage without negatively impacting sample security.

Temperature spikes as a result of door opening were not uniform throughout the chamber. The middle compartment was the most affected by temperature increase, but quick to recover to setpoint. Whereas the bottom section showed the lowest temperature increase. Full study data available on request.

If you would like further information or to discuss your refrigeration requirements, please contact us: enquiries@medlinescientific.com.

[1] Lec Medical model LSFSC242BT (242 L). Full case study available on request.

[2] Liebherr Mediline LCv4010 fridge freezer. Energy usage increased from 0.4 kWh/day to 0.805 kWh/day. Full case study available on request.

[3] Stirling Ultracold SU780XLE. Full case study available on request.

[4] All units were tested at the Learning and Research Centre, University of Bristol. The laboratory space used was air conditioned with an ambient of 23 °C (+/-1.5 °C). This case study used the Logicall Wireless Monitoring system utilizing their energy monitors, temperature probes and online platform to record all the data. In each compartment a UKAS calibrated PT1000 probe was placed in the centrepoint of each shelf. In each unit tested the probe located in the centrepoint of the top compartment was always 14 cm from the top of the chamber. A sample representative probe (PT1000 probe immersed in 5 ml of glycol) was also placed in the centrepoint of the unit (figure 2).